The maple syrup making process is one of long hours and tough labors. Maple tree sap is collected in the spring when the temperatures during the day are warm (above freezing), but fall below freezing overnight. In the southwestern tip of Ohio, we have one of the earliest and shortest sugaring seasons of the year. We tap our trees in mid-January and collect sap through early March. Our season sometimes ends before our colleagues in the northeast begin!

Any type of maple trees will produce sap flow under the right conditions. Sugar maples are certainly the most reliable producers, but are not as common in our area as they are in the northeast. Our southern woods tend to be filled with oak, hackberry, ash, locust, walnut, and hickory. Silver (or soft) maples are the most prevalent in our area where there are maple trees. Large stands of naturally occuring sugar maples are uncommon.

A large percentage of our syrup is made from silver maples, though we also tap sugar maples, a few red maples, some black maples, and even a Norway maple or two. Box elders can also be tapped, but they tend to produce a different flavor, so our farm does not include them in our tapping circuit.

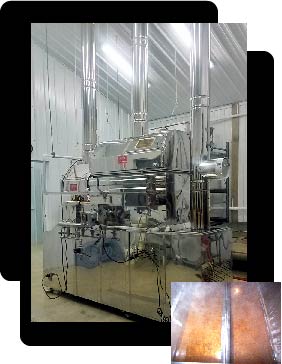

The syrup making process is like a very, very extended version of watching water boil. The sap is loaded continuously into a large stainless steel boiler (called an evaporator) and is boiled for hours on end until enough water has evaporated to leave the remaining mixture at the correct density. The larger and more efficient the evaporator, the quicker it is to make syrup.

After the finished syrup is drawn off the evaporator, it is filtered and bottled, or made into sugar, cream, and candy confections. That’s all there is to it!

The Evaporator

Sap contains, on average, about 2% sugar with the rest being water and other nutrients. Sugar maples produce the highest sugar content and are usually at least 2%. Silver maples tend to have less concentration of sugar (around 1.0 – 1.5%), though some of the silvers in our front yard have topped out near 4% in some years.

The higher the concentration of sugar in the sap, the less sap will be required to make maple syrup. At a 2% sugar concentration, it takes about 50 gallons of sap to make one gallon of maple syrup.

Trees can heal themselves just like people can. After the season is over, the metal taps are pulled from the trees and the small holes left behind close up. In fact, the reason we don’t start even earlier in the season (just in case we get an early heat wave) is that a tapped hole is only good for about 6-8 weeks before it naturally begins to close up.

The following year we carefully choose different spots on the tree to tap.

Healed Tap Hole